Engineering SciBot

Saanavi Goyal, Qaasid Bajwa, Shameeha Naser, & Kehinde Adeoso

Writing for Engineering

Professor Sara Jacobson

November 29, 2022

Introduction

Modern machinery along with technology has provided a great opportunity for humans to gain the most effective results with minimum effort. These machines have elevated the simple innovations to ensure they work in their best form, without having exerting humans and by saving their time. Example of such machinery is scissors. The scissors are a simple machine that has been popular since the 16th century (Britannica). Regular scissors consist of two blades that meet at the handle. It can be used to cut through papers, clothes, food, and other light products. The uses might be undermined however, school students use them for their class projects, chefs use them to cut food in kitchen, and larger end companies also use scissors in their factories to make clothing and fashion items. The large variety of uses in our daily lives makes scissors one of the most practical tools today.

Despite the high demand for scissors in our daily lives, they still require a lot of time and energy that can prove to be tiring, especially if used repeatedly. Although there are significant innovations seen in other machines around us, the scissor and its design have remained relatively the same. Robotic vacuums, such as the Roomba, are an example of significant innovations among practical machines. Likewise, to amend the current versions of the scissor, our innovation, the SciBot, is an automatic scissor that limits human interaction little to no energy spent using it. It consists of two parts: the actual hardware that performs the task of cutting and an app that consists of the software that assigns the task. With modern scissors including laser and electric scissors, the user still has to manually carry out the task while the machine aids in accuracy. The SciBot targets this action and performs the task itself. Much like a Roomba, the SciBot moves by itself to achieve the task at hand, the material that needs to be cut, as it receives information from the app about the material and the path it is designated to follow.

Since scissors are a common practical tool, they are used in a variety of environments. Clothing factories are a specific example of where the SciBot would be most beneficial. Today, one of the most profitable parts of the fashion industry is fast fashion. The idea behind fast fashion is to provide the most trending styles to consumers as fast as possible at affordable prices (Good On You). This strategy requires extensive hours from factory workers to complete as many garments as possible within a single day, leading workers to work excessively past their limits as found in investigations in foreign factories (Business Insider). Though it is a matter of human rights and requires legal action for significant change, implementing devices such as the SciBot would effectively change workers’ routine. Instead of wasting so much energy manually cutting fabrics and other materials, they would instead use the software to inform the device of how to cut and the device would perform the task, saving energy and time.

Past Innovations

There have been two recent innovations in assisted scissors that are similar to what we are trying to implement but have some weaknesses. For example, the company Nueby invented the Lazer Scissors, which have a laser-guided sensor on top to guide you and ensure you always cut a straight line. However, this design makes a person still do manual work, which makes it time consuming as well as an inefficient use of resources. Another design is from SliceProducts, which invented Rotary Scissors, a bladeless tool that reduces the risk of repetitive strain injuries.

However, this design does not guarantee that you cut straight, and it also is an inefficient use of resources as you still need to manually cut. The SciBot allows you to draw out the design you want on an app and then it automatically cuts that design out. This saves you time and money as the design is perfectly shaped. Additionally, you do not have to monitor the scissor because it automatically stops cutting after the design has been finished. Overall, the SciBot is significantly better than both the Lazer Scissors and Rotary Scissors because of the software and efficiency.

Technical Description

Figure 1: The sensors present in a robotic vacuum

Introduction

The SciBot consists of two major components, the product itself and a supporting app. The first part, the product, is hand-sized scissors which will have the blades as well as the software inside. This new technology has been inspired by previously existing robots in the form of automatic vacuums and coffee machines. Figure 1.0 demonstrates the robotic vacuum sensors which inspired the design and concept of SciBot. Similar to those robots, the goal of this innovation is to simplify everyday tasks as much as possible with the help of technology. As the SciBot scissors are autonomous, they do not require much human intervention but instead function through functioning hardware and the detailed software compromised with mobile. The overall concept involves the use of software to scan the desired material onto the SciBot app, allowing the machine to gather data such as the dimensions and type of material. The app also includes features to give the user the choice of shape and design they expect to be cut on the material. The software is connected and installed in the machine which holds other hardware materials like the blade, and blade holder which cuts the required material.

Hardware

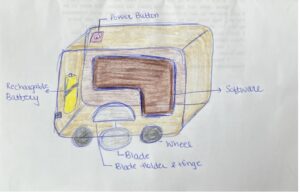

Figure 2.0: The expected design of SciBot

The first part of the SciBot is the hardware. There are many subparts within the hardware, including the aluminum outer case, round blade, blade holder, hinge as well the rechargeable battery connected to the power button. The presence of small black wheels at the bottom of the machine allows the machine to move around the material without cutting unnecessary parts. In other words, the different subparts can be categorized as the aluminum materials, the blade, battery, and power, and lastly the wheels.

- Aluminum

Figure 3.0: Aluminum 6061 Sheet | Figure 4.0: Aluminum Hinge

The majority of the hardware of the SciBot is based on Aluminum 6061. Figure 3 shows an image of a sheet of aluminum which will be used to make the outer layer of the SciBot. As previously mentioned, this design will be a portable size, they would not be larger than the average palm size. Furthermore, this aluminum material will be used to make the blade cover which will store the blade when it is not being used. Lastly, the aluminum hinge is responsible for pulling the blade to the blade holder and rolling it down depending on the commands given by the software.

- The Blade

Figure 5.0: A round blade

The SciBot will have a round blade, as shown in Figure 5.0, which will be used to cut the material designated. The blade will be handled by the software, as it will be activated by the motor only when agreed by the software. This blade will be not as sharp as the material will be placed on a regular hard object; however, the motor will bring the speed which will allow to pace the cutting speed.

- Battery and the Power Button

Figure 5.0: Rechargeable Battery

The rechargeable battery allows the user to keep on using SciBot, which contributes to the long shelf life. Figure 6.0 shows a sample battery which could be used for the SciBot product. The battery will have the same charging points as a laptop, that is lightening to USB. Although the charger will be an accessory to be purchased, users do have the opportunity to connect it to their laptop chargers based on its availability. The power button works as said and turns SciBot on and off.

- Wheels

The wheels in the SciBot will be very small in size and will allow the product to move around and when informed by the software. The wheels share the purpose to avoid manual interference and let the SciBot make cuts whenever and wherever required by the software.

Software

As evident, the functionality of the majority of the hardware highly depends on the software, which will be placed inside the machine. There will be a second yet very significant component of the SciBot, which is the SciBot application. The purpose of this app is to allow the users to be able to make selections about the design and the location of the cut needed. The software itself is divided into two major sections: the scanner and the designer.

The scanner will be the first thing which the user will experience as they open the SciBot app. The scanner will use the camera feature of the mobile/supported device to scan the material, which is expected to be placed on a flat and hard surface. The scanner will identify the dimensions of the material. In case of failure of identification, users have an opportunity to enter the dimensions on their own. Once this step is completed, the next step requires the users to identify the location the cut is desired. This step can be completed by either using the pre-designed shape or using a free-hand pen to make marks on the software. As the marks are confirmed, the SciBot product should be turned on and placed on the material for cutting. Based on the user-gained information, the SciBot will move around with blades out, whenever needed to cut, and will place the blades in the blade holder when needed to move, without making cuts. Lastly, the SciBot will be turned off after all the assigned cutting is completed.

Conclusion

The SciBot is a significant development to a current tool. It allows for maximum efficiency through its advanced software and hardware. Though the SciBot itself can be considered a developing idea, it has the foundation and purpose to be further advanced. It is needed not only in households for practicality but also in manual labor forces where workers heavily depend on tools like modern scissors. The SciBot is a prime example of modern innovations, prioritizing efficiency and practicality, made for the modern consumer.

Design, Time, Cost, & Materials

The design of the SciBot is made to ensure that the scissors are easy to carry as well as easy to use. The automatic scissors have a dimension of 3.5 x 3.5 x 2 inches and are expected to weigh about 6.5 oz or 184.2 grams. This weight can be referenced in comparison to an iPhone 13 which weighs 6.1 oz or 174 grams (Apple). The outer or visible portion of the product will be made of Aluminum 6061 steel. This choice was made as 6061 Aluminum is easy to bend, which we will require to shape the outer side to a square and is water resistant (Jon, 2021). It is significant to ensure that the steel is water resistant as there are software and sensors which will be inside the SciBot, and water interference can damage the machine. It is expected that the steel will cost about $5 for each scissor when purchased in a bulk of 100+ pieces.

Additionally, the outside will have 2 mini wheels, which will allow the scissors to move across the desired area for cutting. Each pair is expected to cost about $7-9 depending on the quantity. Furthermore, the round blade to cut will have a 200mm diameter and will cost about $3-4 each in bulk. The blade will be attached to a hinge which will bull the blades up to its designated blade holder, when there is no cutting required. The pulling hinge and blade holder will be made of the same Aluminum steel as the outer and will cost $2 in bulk. Inside the SciBot, there will be rechargeable batteries, similar to what are used in smartphones and laptops and each battery will cost $20. The chargers would be an accessory not provided due to affordability, but it will be a Type C and USB charger, which are used usually in households for charging devices. Lastly, the software itself will be inserted into the machine, but will not have an individual cost as it will all be developed separately. The software production is expected to be the most expensive aspect of the design, however, with bulk quantity machines being manufactured at once, it will be about $10 for each scissor.

The SciBot will be built to a portable design that is accessible for the users to use daily and travel to different places when required. To ensure that the product is affordable to a larger population, the cost was minimized as much as possible. Inclusive of labor, manufacturing, and materials, the unit price for each SciBot will be $75. At this cost, users will have access to the SciBot scissors and the accompanying app for free. It is expected that about 100 SciBot Scissors will be made in a month, and will last for years and years, due to its rechargeable battery.

At the cost of $75, SciBot hopes to provide a new generation of scissors for school, work, college, and factories with minimum effort and human interaction while providing the most error-proof cutting software.

Works Cited

Apple – iPhone 13 . Apple. (n.d.). Retrieved November 28, 2022, from https://www.apple.com/shop/buy-iphone/iphone-13

Gaur, A. et al (n.d.). Scissors. Encyclopædia Britannica. Retrieved November 28, 2022, from https://www.britannica.com/technology/scissors

Goyal, Saanavi. (2022). SciBot [Drawing].

Jackson, S. (2022, October 16). Shein factory employees are working 18-hour days for pennies per garment and washing their hair on lunch breaks because they have so little time off, new report finds. Business Insider. Retrieved November 28, 2022, from https://www.businessinsider.com/shein-factory-workers-18-hour-shifts-paid-low-wages-report-2022-10

Jon. (2021, August 16). The main advantages of 6061 Aluminum. Thin Metal Sales. Retrieved November 28, 2022, from https://www.thinmetalsales.com/blog/the-main-advantages-of-6061-aluminum/

Laser Scissors. Amazon. (n.d.). Retrieved November 28, 2022, from https://www.amazon.com/Stalwart-75-PT1022-Cordless-Cardboard-Rechargeable/dp/B0733HNKRZ

Layton, J. (2005). Roomba Red []. How Stuff Works. https://electronics.howstuffworks.com/gadgets/home/robotic-vaccum

Rauturier, S. (2022, June 23). What is fast fashion and why is it so bad? Good On You. Retrieved November 28, 2022, from https://goodonyou.eco/what-is-fast-fashion/

Rotary Scissors with ergonomic bladeless design. slice. (n.d.). Retrieved November 28, 2022, from https://www.sliceproducts.com/products/rotary-scissors?utm_source=google&utm_medium=cpc&utm_term=&utm_content=&utm_campaign=17304683660&matchtype=&device=c&gclid=Cj0KCQiA1NebBhDDARIsAANiDD1rQRyxZMWgIvl_1SbxJx2L1Mf-TvQ6dPzoESnOm–gDFtP4e6WSCYaArHBEALw_wcB

6061 aluminum sheet. Midwest Steel & Aluminum. (n.d.). Retrieved November 28, 2022, from https://www.midweststeelsupply.com/store/6061aluminumsheet